MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

Medium density fibreboard (MDF) is very commonly used in material in furniture manufacturing, construction and most popularly used in interior decoration.

With help new emerging printing technologies different customized printing techniques can be used to cater to customize customer needs for personalized demands and interior decorations.

The same is done with the use of Digital printing technique the printing can be done on either one or both sides with a standard colour option or high quality printed images.

High glossy UV board means painting on MDF, plywood, widely used for furniture, carbinet etc.

If you are interested in high glossy UV board , please see more at https://chinafiberboard.com/ This video shows how produce the glossy UV board, this is bottom 5 floors, face 2 floors. YWe warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

el: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

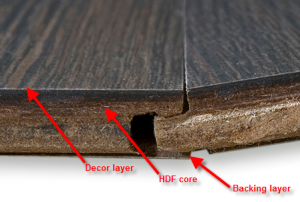

One of the key areas to ask about when shopping for laminate and engineered wood floors is the core layer, which we talk about a bit on our 5 Things You Need To Know Before You Buy Laminate Flooring. The materials typically used in the making of a core layer is high-density fiberboard (HDF) and medium-density fiberboard (MDF). Given that it is an important aspect when it comes to the anatomy of a floor, and important when you’re buying floors, I thought it made sense to talk about it a bit.

Fiberboard is a wood byproduct, known as an engineered wood product because raw materials are taken and processed into a versatile and durable material. It’s used in flooring as core material, of course. But, it’s also used for furniture manufacturing, designed not to split or crack.

Fiberboard is made through a compression process, where wood fibers are bonded together, specifically for the use of backing or of reinforcing a veneer, and most often with a resin to keep it stable. On laminate flooring and engineered hardwood floors, the fiberboard core are sandwiched between the decor layer or veneer layer, and the backing layer.

Take a look:

HDF is MDF are made in a similar process, although the compression levels are in a slightly lower range with MDF from 600-800 kg/m3. HDF is processed in a range from 600-1450 kg/M3. Fiberboard cores are checked for emissions levels, both when they’re manufactured, and afterward too before they’re shipped as product. This is mainly due to the use of resins and glue that are used to bind the materials, and the importance placed on reducing off-gassing as much as possible.

One of the pieces of advice is to always choose HDF when shopping for laminate floors, if you can. The ressistance to moisture, and to shrinkage and expansion in HDF is much higher. This makes for a more stable core, which is the job of the core in any case – to give you a more stable floor overall. MDF will still serve you, of course. But, HDF is preferable for better performance.

Physical and mechanical properties

Because of its uniform structure and high bonding strength between fibers, it has good static bending strength, plane tensile strength and elastic modulus. However, because MDF is made of wood, it completely changes the structure of wood, so its water absorption, water absorption, thickness expansion rate is higher, nail grip strength is worse than particleboard.

Decorative performance

Because the surface of MDF is smooth, it is easy to stick veneer materials such as veneer and tissue paper, so it is easy to paint and save paint.

Additive performance

MDF can be produced from several millimeters to tens of millimeters in thickness. It can replace wood and square wood of any thickness, and has good machinability, sawing, drilling, grooving, tenoning, sanding and carving.

Plywood is a three-layer or multi-layer board-like material made of wood pieces that are peeled into veneer or sliced into veneer from wood, and then glued with adhesive. Usually, odd-numbered veneers are used, and adjacent veneers are used The fiber directions are glued perpendicular to each other.

Plywood is one of the commonly used materials for furniture and is one of the three major panels of wood-based panels. It can also be used as a material for aircraft, ships, trains, automobiles, buildings, and packaging boxes. A group of veneers is usually formed by gluing the adjacent layers of wood grains perpendicular to each other. The surface board and the inner board are usually arranged symmetrically on both sides of the central layer or the core. A slab made of glued veneers crisscrossed in the direction of the wood grain is pressed under heating or non-heating conditions. The number of layers is generally odd, and a few have even numbers. There is little difference in physical and mechanical properties in the vertical and horizontal directions. Commonly used types of plywood are three plywood, five plywood and so on. Plywood can improve the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, and the thickness specifications are generally: 3, 5, 9, 12, 15, 18mm , etc. The main tree species are: beech, camphor, willow, poplar, eucalyptus, etc.

Plywood is a board of plies or sheets of real wood glued together. The arrangement of these sheets which have grains will determine the strength of the whole material. There are numerous instances where plywood is used for different purposes. Some of its applications are on floors, roofs, furniture which are custom built, walls and kitchen cabinets. Below are the types of plywood:

Hardwood plywood

This type of plywood has great strength and stiffness. With great impact resistance, hardwood plywood is used for wall structures. Although it will require finishing for a smooth attractive look, hardwood plywood can be used in making furniture. Hardwood plywood can be made from oak, mahogany, birch or maple.

Softwood plywood

Softwood plywood is a product derived from softwood trees such as fir, cedar and spruce. Softwood plywood is mostly used in furniture making whereas hardwood is applied in construction. Moreover, softwood plywood is less expensive than hardwood plywood but less durable than the latter.

Tropical plywood

This type of plywood is derived from tropical wood. It has a better strength and quality than softwood plywood. This has brought about an increase in its demand worldwide. There has also been an increase in its price as buyers search for reliable sources in Asia and Africa.

Advantages of plywood

Disadvantages of plywood

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.