Many people wondering the difference between MDF vs solid wood. MDF is an abbreviation for Medium Density Fiberboard. People tend to look down on MDF and automatically assume solid wood is the better choice.

Of course, solid wood, like anything has its pros and cons. The benefits of solid wood: it’s strong, sturdy, and features a beautiful natural look to it with grain patterns. If you’re looking for something to last forever, solid wood is a great choice. Each species of wood is different and some have longer longevity than others, but people are drawn to it. We love to have the authenticity of solid wood, which I completely understand. The beauty of natural wood is unbeatable.

However, wood contracts or expands when it is exposed to changing heat and humidity. Unless your home is a controlled climate, cabinets made from wood can shrink or crack over time. Something most people don’t even think about is the possibility of bug infestation in your wood. It is vulnerable to pests which means it requires some maintenance.

I’ve had so many people turn away the minute they hear there is MDF in a product. Man-made products are not as popular as the natural material. But why no love for this product? MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns. This will result in a smoother finish on the cabinets. MDF is also less expensive, which is sometimes a big selling point for some people. Depending on budget, others are willing to spend the extra money to purchase the all wood cabinets.

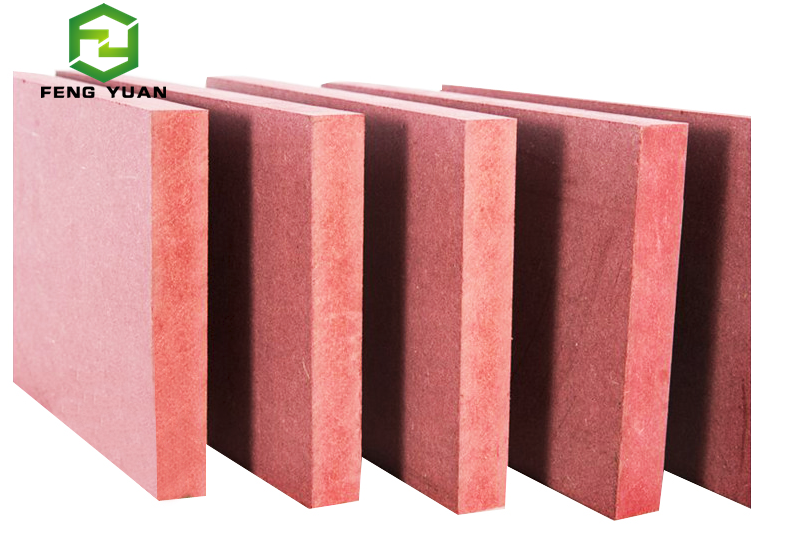

This new colour is custom-made, regular for furniture, cabinet, etc.

Colour is light beige,light grey, can be laminated on mdf, HMR mdf, etc.

Shipment is suit for bulk shipping ,container shipping/

Furniture made from solid wood is typically thought of as beautiful, timeless and high quality. Whether it’s oak, pine or maple, there are plenty of choices when it comes to using wood for furniture.

In comparison, MDF (Medium Density Fiber-Board) is made with recycled timer and fiber materials, mixed with resin-based glue and compacted very tightly together.

Typically, MDF is seen as a cheaper alternative to solid wood and is often perceived to be lower in quality. However, in recent years there has been a rapid resurgence in flat-pack furniture being manufactured with MDF. This is largely due to the lower material costs, but also because it’s easy to store compactly.

So, with advantages and disadvantages for both solid wood and MDF, which is the better option?

Cost

MDF’s core ingredient is sawdust and small chippings of other timbers. These are all collected waste products from the machining process which makes the material cost much lower than plywood and solid wood.

Size variety

MDF sheets are available off-the-shelf in over 100 different thicknesses, starting from 2mm and going right up to 60mm. The wide-ranging number of options available makes it very easy to get the thickness of “wood” that is required for the application at hand.

Ugly raw material

Solid wood is renowned for its astounding natural beauty. MDF is not the most attractive natural colour and lacks the character and features found in solid wood and plywood.

Less warping issues

Unlike solid wood, MDF will remain strong in areas where there is high humidity and moisture. This is because MDF is able to consistently shrink and expand without the different parts of the grain working against each other.

Consistent material

MDF doesn’t have a directional grain like plywood and solid wood which makes it ideal if you’re cutting intricate details or moulding; other materials would splinter or the cut will not be as smooth.

Smooth surface and cuts

MDF is pressed extremely compact during the manufacturing process with large steel plates, which makes the overall sheet extremely flat and smooth. This makes MDF ideal for painting, laminating or attaching veneers. Once sheets are cut to size, the edges remain smooth, whereas on solid wood or plywood the edges can splinter or have voids due to the natural knots and grain in the wood。

Weak material

MDF lacks the directional grain that gives solid wood and plywood its strength and structural integrity. Even though a lot of shelving and cabinets are remade from MDF, they require a solid timber frame to provide support or must be fixed in a way to ensure it does not sag over time.

Cracks and splits

You have to be extremely careful when screwing into MDF as it’s liable to crack or split across its fibers. Pilot holes are essential before screwing into MDF to make room for the screw and reduce the chances of the material splitting – although it’s important to note that MDF can still split even if you use a regular screw. Since regular wood screws tapered shape will make MDF split, a straight sharked screw is required.

Restrictions on finish

If you’re wanting to match an existing furniture finish with a wood stain, it’s best to not use MDF. MDF will soak up all of the liquid and not give the desired colour effect. It’s best to use this material if the plan is to have it painted.

Contains VOC’s

The glue that holds all of the fibres together contains formaldehyde. When it’s cut, sanded or machined, it kicks out a lot of dust that can cause irritation to the lungs and eyes. Long term effects can include lung, nose and throat cancer.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.