This questions has been asked by many persons, now let's introduce MDF here.

MDF , the full name is Medium Density Fiberboard, that’s an inexpensive and durable option for many carpentry projects. Medium-density fiberboard is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting.

MDF is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure, it also can be called fiberboard, some high density ≥800,called HDF, but it only have density & thickness difference.

MDF is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting

Yes, the contect of formadehydele can be controlled, the grade can be E1, E0, some grade will be lower than logs.

Advantages of MDF Wood

MDF is inexpensive.

MDF uses recycled wood, which is environmentally-friendly.

Veneers can be attached to MDF to make it look like real wood.

MDF will not expand and contract in the heat and humidity like solid wood can.

MDF is easy to paint in a variety of colors and easier to shape than solid wood.

MDF doesn’t have knots that can make a piece hard to attach.

MDF is resistant to pests, such as termites, due to the chemicals used in its construction.

Disadvantages of MDF Wood

If MDF is chipped or cracked, you cannot repair or cover it easily.

MDF can swell if it touches water.

There’s no natural grain on MDF wood.

Small amounts of formaldehyde may be off-gassed during construction, and it’s less child-friendly than solid wood.

MDF has glue in it that can make it hard to sink certain types of fasteners into it.

If you are interested in MDF,HDF, MELAMINE MDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

All the wood based panel which using melamine Laminate technology can be called melamine boards. Common melamine board based with MDF board, particleboard, and plywood. Melamine MDF board, as the name implies, is based of MDF, melamine paper can be various colours, white, black, wood grain,etc.

Usually, when we talk about Melamine boards, we talk about Laminates and baseboards. But in fact is much more complexed. Laminate is generally composed of ① surface paper, ②decorative paper, ③cover paper, and ④bottom paper.

① The surface paper is placed on the top layer of the decorative board. It protects the decorative paper and makes the surface of the board after heating and pressing highly transparent. The board surface is hard and abrasion-resistant. This paper requires good water absorption, white and clean, and transparent after dipping.

② Decorative paper, that is, wood grain paper, is an important part of the decorative board. It has a base color or no base color and is printed into various patterns of decorative paper. It is placed under the surface paper and mainly plays a decorative role. This layer requires Paper has good hiding power, impregnation, and printing performance.

③ Cover paper, also called titanium white paper, is generally placed under decorative paper when manufacturing light-colored decorative boards to prevent the underlying phenolic resin from penetrating the surface. Its main function is to cover the color spots on the surface of the substrate. Therefore, good coverage is required. The above three types of paper were each impregnated with melamine resin.

④ Bottom paper is the base material of the decorative board. It plays a role in the mechanical properties of the board. It is made by impregnating with phenolic resin glue and dried. Several layers can be determined according to the application or the thickness of the decorative board during production.

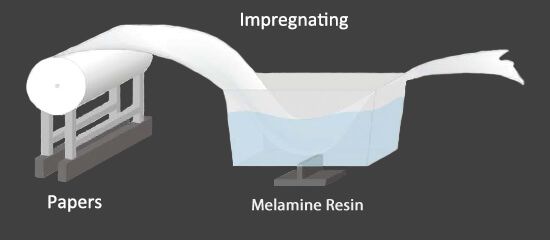

To turn the papers to laminates, we need to impregnating them in melamine resins, mealmine resin is used for stick the paper on surface of MDF.

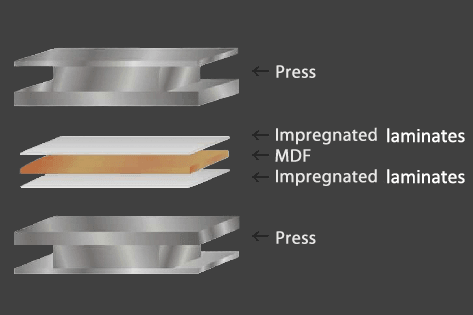

when we had Melamine Laminates, then use a hot press machine to laminated it with MDF Board.

This the process how the melamine MDF board be produced.The Impregnating Process normally finished by the laminates factory, then we buy melamine laminates from them and produce melamine Paper

You can also view the above video to see how it works.

If you are interested in melamine melamine MDF , please see more at https://chinafiberboard.com/

We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely.

We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whats app: +8615868403313

Email: sales@fengyuanwooden.com

What is Hot pressing for hardboard? This is the questions we asked mostly from our clients, let's discuss it together.

The hot-pressed wet-process method produces a hard-fiber board with a pressure of 5 MPa and a dry method of 7 MPa. Above this pressure, the bending strength is reduced. The pressure required for the semi-dry method is between the two, at 6 MPa. The wet-formed slab is pressed into a hard fiberboard at a pressure of up to 10 MPa. The temperature used in the wet pressing method is 200 to 220 °C.

There is no drying stage when dry pressing, the temperature is based on the rapid curing of the adhesive, generally 180 ~ 200 ° C; when using hardwood as raw material, the hot pressing temperature can be appropriately increased, up to 260 ° C. The semi-dry hot pressing temperature should not exceed 200 ° C to prevent the melting of lignin and sugar hydrolysis coking in the slab, so that the strength of the product is significantly reduced.

The temperature required to produce a hard board by wet drying is 230 to 250 °C. During the hot pressing process, the temperature difference between the surface layer and the core layer of the slab may occur, and the temperature difference of the core layer of the medium-density slab having a large thickness may reach 40 to 60 ° C, which affects the curing rate of the core resin. Conventional heating and high frequency heating can be used to eliminate temperature differences and shorten the hot pressing cycle.

After hot processing, hardboard, mdf, plywood will be have a good quality & stable technical nature.

This new colour is custom-made, regular for furniture, cabinet, etc.

Colour is light beige,light grey, can be laminated on mdf, HMR mdf, etc.

Shipment is suit for bulk shipping ,container shipping/

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.