This questions has been asked by many persons, now let's introduce MDF here.

MDF , the full name is Medium Density Fiberboard, that’s an inexpensive and durable option for many carpentry projects. Medium-density fiberboard is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting.

MDF is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure, it also can be called fiberboard, some high density ≥800,called HDF, but it only have density & thickness difference.

MDF is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting

Yes, the contect of formadehydele can be controlled, the grade can be E1, E0, some grade will be lower than logs.

Advantages of MDF Wood

MDF is inexpensive.

MDF uses recycled wood, which is environmentally-friendly.

Veneers can be attached to MDF to make it look like real wood.

MDF will not expand and contract in the heat and humidity like solid wood can.

MDF is easy to paint in a variety of colors and easier to shape than solid wood.

MDF doesn’t have knots that can make a piece hard to attach.

MDF is resistant to pests, such as termites, due to the chemicals used in its construction.

Disadvantages of MDF Wood

If MDF is chipped or cracked, you cannot repair or cover it easily.

MDF can swell if it touches water.

There’s no natural grain on MDF wood.

Small amounts of formaldehyde may be off-gassed during construction, and it’s less child-friendly than solid wood.

MDF has glue in it that can make it hard to sink certain types of fasteners into it.

If you are interested in MDF,HDF, MELAMINE MDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

OSB , full name is Oriented strand board , after it has been invented, mostly popular used in home ,hotel, baber shop etc. Due to its healthy formaldehyde content, and recommend a good use when in decration.But most of people dont know how to produce it, now let us know this knowledge from above photo & our video. If you want to know more about our OSB products, pls free contact us by email:sales@fengyuanwooden.com.

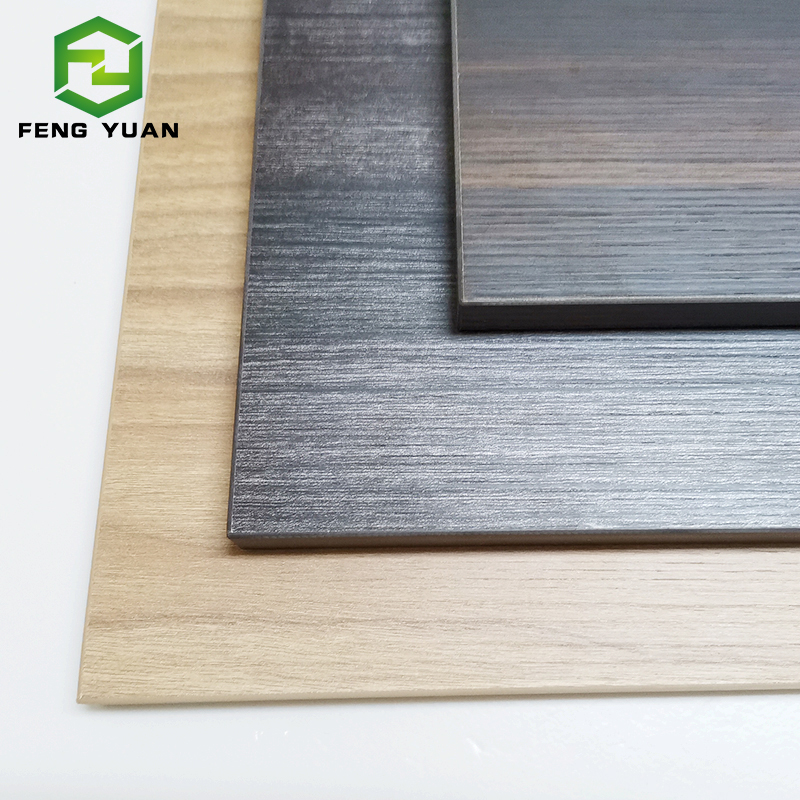

All the wood based panel which using melamine Laminate technology can be called melamine boards. Common melamine board based with MDF board, particleboard, and plywood. Melamine MDF board, as the name implies, is based of MDF, melamine paper can be various colours, white, black, wood grain,etc.

Usually, when we talk about Melamine boards, we talk about Laminates and baseboards. But in fact is much more complexed. Laminate is generally composed of ① surface paper, ②decorative paper, ③cover paper, and ④bottom paper.

① The surface paper is placed on the top layer of the decorative board. It protects the decorative paper and makes the surface of the board after heating and pressing highly transparent. The board surface is hard and abrasion-resistant. This paper requires good water absorption, white and clean, and transparent after dipping.

② Decorative paper, that is, wood grain paper, is an important part of the decorative board. It has a base color or no base color and is printed into various patterns of decorative paper. It is placed under the surface paper and mainly plays a decorative role. This layer requires Paper has good hiding power, impregnation, and printing performance.

③ Cover paper, also called titanium white paper, is generally placed under decorative paper when manufacturing light-colored decorative boards to prevent the underlying phenolic resin from penetrating the surface. Its main function is to cover the color spots on the surface of the substrate. Therefore, good coverage is required. The above three types of paper were each impregnated with melamine resin.

④ Bottom paper is the base material of the decorative board. It plays a role in the mechanical properties of the board. It is made by impregnating with phenolic resin glue and dried. Several layers can be determined according to the application or the thickness of the decorative board during production.

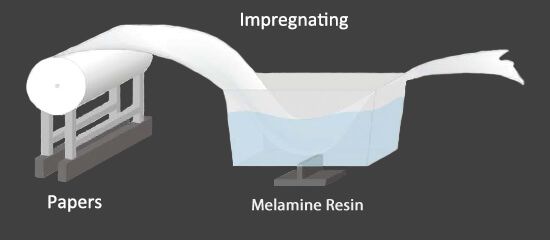

To turn the papers to laminates, we need to impregnating them in melamine resins, mealmine resin is used for stick the paper on surface of MDF.

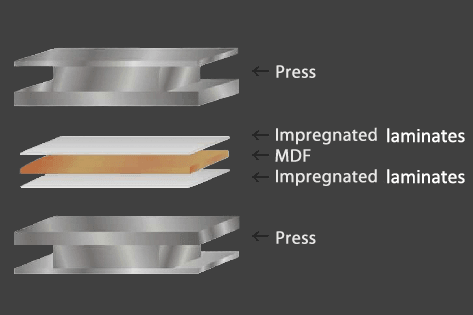

when we had Melamine Laminates, then use a hot press machine to laminated it with MDF Board.

This the process how the melamine MDF board be produced.The Impregnating Process normally finished by the laminates factory, then we buy melamine laminates from them and produce melamine Paper

You can also view the above video to see how it works.

If you are interested in melamine melamine MDF , please see more at https://chinafiberboard.com/

We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely.

We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whats app: +8615868403313

Email: sales@fengyuanwooden.com

The UV High Gloss Board are made with UV coating applied to a panel surface that could be Melamine impregnated Pre-lam. UV means Ultra Violet Coating, ts core part is made of MDF wood and then it is given to UV coated coating. This is a process of drying the lacquer by UV rays in a series of closed chambers.

It will have 7 layer painting on the melamine paper.

The application in cupboard & kitchen shutters, furniture panels, wall relief panelling ,etc.

If you are interested in high gossy UV board , please see more at https://chinafiberboard.com/ This video shows how produce the UV board, this is bottom 5 floors, face 2 floors. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713 Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

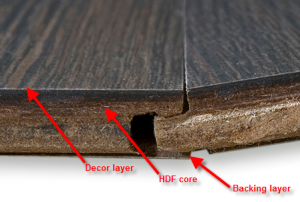

One of the key areas to ask about when shopping for laminate and engineered wood floors is the core layer, which we talk about a bit on our 5 Things You Need To Know Before You Buy Laminate Flooring. The materials typically used in the making of a core layer is high-density fiberboard (HDF) and medium-density fiberboard (MDF). Given that it is an important aspect when it comes to the anatomy of a floor, and important when you’re buying floors, I thought it made sense to talk about it a bit.

Fiberboard is a wood byproduct, known as an engineered wood product because raw materials are taken and processed into a versatile and durable material. It’s used in flooring as core material, of course. But, it’s also used for furniture manufacturing, designed not to split or crack.

Fiberboard is made through a compression process, where wood fibers are bonded together, specifically for the use of backing or of reinforcing a veneer, and most often with a resin to keep it stable. On laminate flooring and engineered hardwood floors, the fiberboard core are sandwiched between the decor layer or veneer layer, and the backing layer.

Take a look:

HDF is MDF are made in a similar process, although the compression levels are in a slightly lower range with MDF from 600-800 kg/m3. HDF is processed in a range from 600-1450 kg/M3. Fiberboard cores are checked for emissions levels, both when they’re manufactured, and afterward too before they’re shipped as product. This is mainly due to the use of resins and glue that are used to bind the materials, and the importance placed on reducing off-gassing as much as possible.

One of the pieces of advice is to always choose HDF when shopping for laminate floors, if you can. The ressistance to moisture, and to shrinkage and expansion in HDF is much higher. This makes for a more stable core, which is the job of the core in any case – to give you a more stable floor overall. MDF will still serve you, of course. But, HDF is preferable for better performance.

Physical and mechanical properties

Because of its uniform structure and high bonding strength between fibers, it has good static bending strength, plane tensile strength and elastic modulus. However, because MDF is made of wood, it completely changes the structure of wood, so its water absorption, water absorption, thickness expansion rate is higher, nail grip strength is worse than particleboard.

Decorative performance

Because the surface of MDF is smooth, it is easy to stick veneer materials such as veneer and tissue paper, so it is easy to paint and save paint.

Additive performance

MDF can be produced from several millimeters to tens of millimeters in thickness. It can replace wood and square wood of any thickness, and has good machinability, sawing, drilling, grooving, tenoning, sanding and carving.

What is the Characteristics and uses of low density fiberboard, medium density fiberboard, high density fiberboard?

Medium density board: the density is 550 kg - 880 kg / m3. Its main advantages are low price relative to logs, easy processing, uniform material, good physical properties, waterproof and moisture-proof after adding paraffin and other items. It is mainly used for furniture and building materials.

High density board: the density is more than 2880 kg / m3, its dimensional stability is good, easy to carry out surface decoration treatment. The internal structure is fine, which can be processed into various special-shaped edges, and it does not need to seal the edge directly, which can achieve better modeling effect. organization structure

It is suitable to replace natural wood as structural material, and is widely used in interior and exterior decoration, office high-grade furniture, audio, interior decoration of high-grade cars, as well as calculation

Anti static floor, wall panel, anti-theft door, wall panel, clapboard, etc. It is also a good material for packaging. In recent years, it has replaced the high-grade hardwood and directly processed into composite floor and laminate floor; It is also used in the goods protection frame in the process of transportation, as well as in the modern home decoration frame less painting, such as the national registered trademark visual life frame less painting is so applied, making the home life more environmentally friendly.

Low density board: low density board is below 550 kg / m3, the fiber of low density fiberboard is not as tight as high density board. General home decoration is MDF, low density board with less.

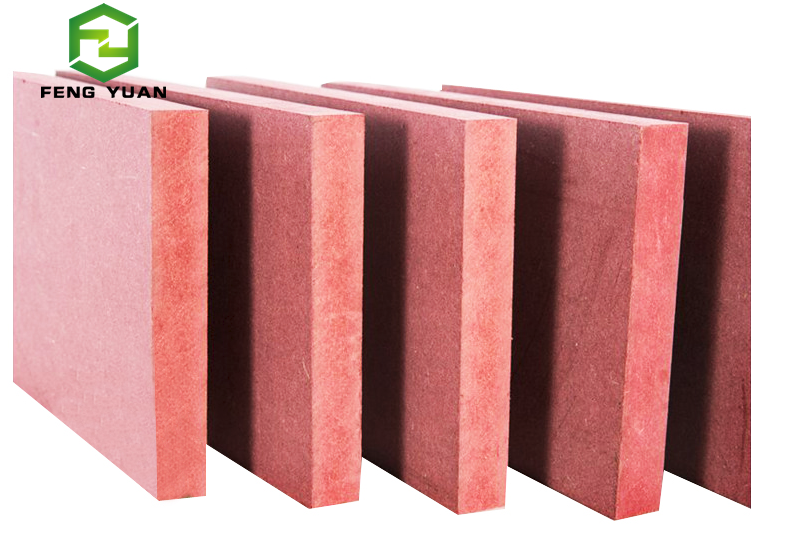

When buying boards, I wonder if you have noticed such a special board -fire-retardant MDF board. The intuitive characteristic of this type of board is the red or pink appearance, which is distinguished from ordinary density boards by adding red dye during the production process. Its flame-retardant properties are also formed by adding flame-retardant chemical components during the manufacturing process.

Fire-retardant panels have attracted a lot of attention since they came out. Because of their superior flame-retardant and safety performance than ordinary MDF, it has been widely used in international brand display props, entertainment venues decoration, domestic shopping malls Cinemas, airports, hotels and other public places.

Due to the uneven quality of the fire-retardant boards circulating in the market, how to buy high-quality fire-retardant MDF? Here, FengYuan will briefly introduce to you the three purchase techniques of fire-retardant MDF:

1. Brand identification method

Flame-retardant MDF is a product with relatively high production technology requirements. Generally speaking, only larger manufacturers have the ability to produce. When buying flame-retardant MDF, pay attention to the side of the board. Big brands will indicate their factory name, flame-retardant grade and other information on the edge.

2. Flame retardant report identification method

When purchasing, you can ask the dealer to provide the flame retardant grade test report, the test report will list the flame retardant grade of the board in detail, and the parameter information is for the purchaser to view. Since most manufacturers will only test some representative sizes, when the required size is not reported, it is also possible to select a test report of a similar size.

3. Identification method of excellent dealers

It is also a better way to choose an excellent and well-known board distributor. Such distributors have a long history of development, possess brand value, and have more reliable board quality.

As one of the company's high-quality products, the flame-retardant board has indeed been favored by many buyers for its own excellent performance, and its future application scope and development space will be broader.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.