This questions has been asked by many persons, now let's introduce MDF here.

MDF , the full name is Medium Density Fiberboard, that’s an inexpensive and durable option for many carpentry projects. Medium-density fiberboard is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting.

MDF is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure, it also can be called fiberboard, some high density ≥800,called HDF, but it only have density & thickness difference.

MDF is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting

Yes, the contect of formadehydele can be controlled, the grade can be E1, E0, some grade will be lower than logs.

Advantages of MDF Wood

MDF is inexpensive.

MDF uses recycled wood, which is environmentally-friendly.

Veneers can be attached to MDF to make it look like real wood.

MDF will not expand and contract in the heat and humidity like solid wood can.

MDF is easy to paint in a variety of colors and easier to shape than solid wood.

MDF doesn’t have knots that can make a piece hard to attach.

MDF is resistant to pests, such as termites, due to the chemicals used in its construction.

Disadvantages of MDF Wood

If MDF is chipped or cracked, you cannot repair or cover it easily.

MDF can swell if it touches water.

There’s no natural grain on MDF wood.

Small amounts of formaldehyde may be off-gassed during construction, and it’s less child-friendly than solid wood.

MDF has glue in it that can make it hard to sink certain types of fasteners into it.

If you are interested in MDF,HDF, MELAMINE MDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

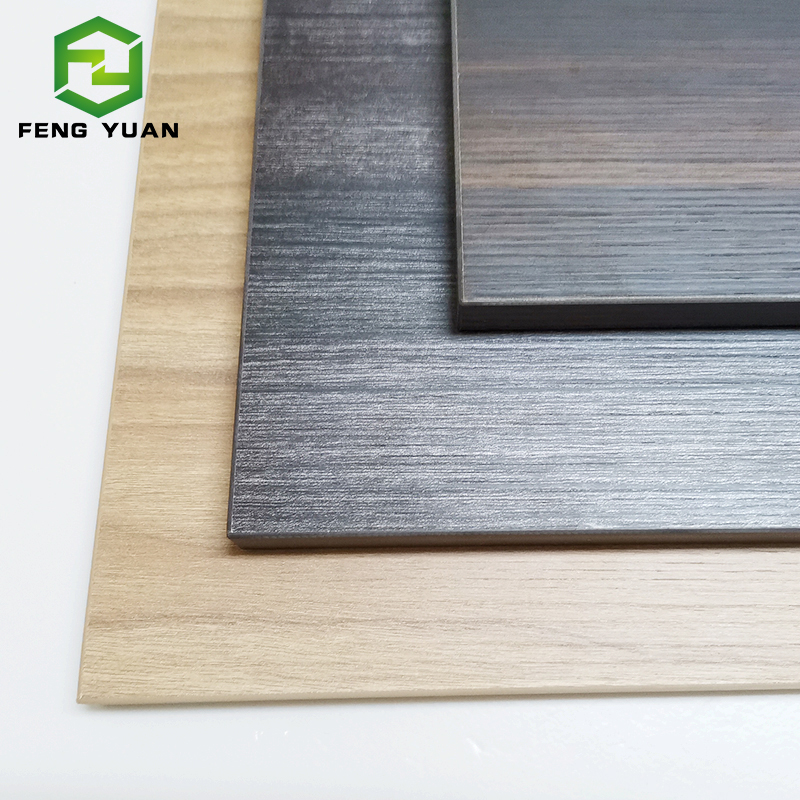

MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

Physical and mechanical properties

Because of its uniform structure and high bonding strength between fibers, it has good static bending strength, plane tensile strength and elastic modulus. However, because MDF is made of wood, it completely changes the structure of wood, so its water absorption, water absorption, thickness expansion rate is higher, nail grip strength is worse than particleboard.

Decorative performance

Because the surface of MDF is smooth, it is easy to stick veneer materials such as veneer and tissue paper, so it is easy to paint and save paint.

Additive performance

MDF can be produced from several millimeters to tens of millimeters in thickness. It can replace wood and square wood of any thickness, and has good machinability, sawing, drilling, grooving, tenoning, sanding and carving.

Plywood is a three-layer or multi-layer board-like material made of wood pieces that are peeled into veneer or sliced into veneer from wood, and then glued with adhesive. Usually, odd-numbered veneers are used, and adjacent veneers are used The fiber directions are glued perpendicular to each other.

Plywood is one of the commonly used materials for furniture and is one of the three major panels of wood-based panels. It can also be used as a material for aircraft, ships, trains, automobiles, buildings, and packaging boxes. A group of veneers is usually formed by gluing the adjacent layers of wood grains perpendicular to each other. The surface board and the inner board are usually arranged symmetrically on both sides of the central layer or the core. A slab made of glued veneers crisscrossed in the direction of the wood grain is pressed under heating or non-heating conditions. The number of layers is generally odd, and a few have even numbers. There is little difference in physical and mechanical properties in the vertical and horizontal directions. Commonly used types of plywood are three plywood, five plywood and so on. Plywood can improve the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, and the thickness specifications are generally: 3, 5, 9, 12, 15, 18mm , etc. The main tree species are: beech, camphor, willow, poplar, eucalyptus, etc.

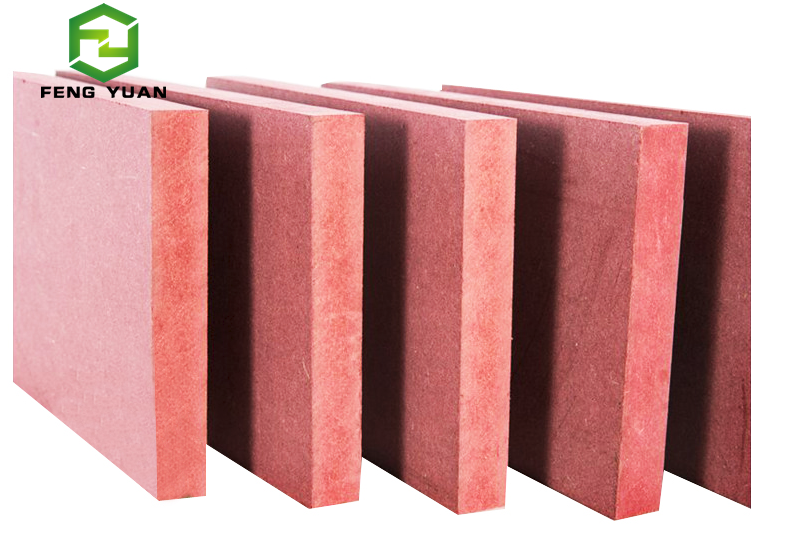

When buying boards, I wonder if you have noticed such a special board -fire-retardant MDF board. The intuitive characteristic of this type of board is the red or pink appearance, which is distinguished from ordinary density boards by adding red dye during the production process. Its flame-retardant properties are also formed by adding flame-retardant chemical components during the manufacturing process.

Fire-retardant panels have attracted a lot of attention since they came out. Because of their superior flame-retardant and safety performance than ordinary MDF, it has been widely used in international brand display props, entertainment venues decoration, domestic shopping malls Cinemas, airports, hotels and other public places.

Due to the uneven quality of the fire-retardant boards circulating in the market, how to buy high-quality fire-retardant MDF? Here, FengYuan will briefly introduce to you the three purchase techniques of fire-retardant MDF:

1. Brand identification method

Flame-retardant MDF is a product with relatively high production technology requirements. Generally speaking, only larger manufacturers have the ability to produce. When buying flame-retardant MDF, pay attention to the side of the board. Big brands will indicate their factory name, flame-retardant grade and other information on the edge.

2. Flame retardant report identification method

When purchasing, you can ask the dealer to provide the flame retardant grade test report, the test report will list the flame retardant grade of the board in detail, and the parameter information is for the purchaser to view. Since most manufacturers will only test some representative sizes, when the required size is not reported, it is also possible to select a test report of a similar size.

3. Identification method of excellent dealers

It is also a better way to choose an excellent and well-known board distributor. Such distributors have a long history of development, possess brand value, and have more reliable board quality.

As one of the company's high-quality products, the flame-retardant board has indeed been favored by many buyers for its own excellent performance, and its future application scope and development space will be broader.

Many people wondering the difference between MDF vs solid wood. MDF is an abbreviation for Medium Density Fiberboard. People tend to look down on MDF and automatically assume solid wood is the better choice.

Of course, solid wood, like anything has its pros and cons. The benefits of solid wood: it’s strong, sturdy, and features a beautiful natural look to it with grain patterns. If you’re looking for something to last forever, solid wood is a great choice. Each species of wood is different and some have longer longevity than others, but people are drawn to it. We love to have the authenticity of solid wood, which I completely understand. The beauty of natural wood is unbeatable.

However, wood contracts or expands when it is exposed to changing heat and humidity. Unless your home is a controlled climate, cabinets made from wood can shrink or crack over time. Something most people don’t even think about is the possibility of bug infestation in your wood. It is vulnerable to pests which means it requires some maintenance.

I’ve had so many people turn away the minute they hear there is MDF in a product. Man-made products are not as popular as the natural material. But why no love for this product? MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns. This will result in a smoother finish on the cabinets. MDF is also less expensive, which is sometimes a big selling point for some people. Depending on budget, others are willing to spend the extra money to purchase the all wood cabinets.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.