MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

One of the key areas to ask about when shopping for laminate and engineered wood floors is the core layer, which we talk about a bit on our 5 Things You Need To Know Before You Buy Laminate Flooring. The materials typically used in the making of a core layer is high-density fiberboard (HDF) and medium-density fiberboard (MDF). Given that it is an important aspect when it comes to the anatomy of a floor, and important when you’re buying floors, I thought it made sense to talk about it a bit.

Fiberboard is a wood byproduct, known as an engineered wood product because raw materials are taken and processed into a versatile and durable material. It’s used in flooring as core material, of course. But, it’s also used for furniture manufacturing, designed not to split or crack.

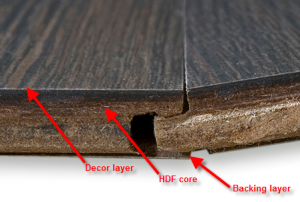

Fiberboard is made through a compression process, where wood fibers are bonded together, specifically for the use of backing or of reinforcing a veneer, and most often with a resin to keep it stable. On laminate flooring and engineered hardwood floors, the fiberboard core are sandwiched between the decor layer or veneer layer, and the backing layer.

Take a look:

HDF is MDF are made in a similar process, although the compression levels are in a slightly lower range with MDF from 600-800 kg/m3. HDF is processed in a range from 600-1450 kg/M3. Fiberboard cores are checked for emissions levels, both when they’re manufactured, and afterward too before they’re shipped as product. This is mainly due to the use of resins and glue that are used to bind the materials, and the importance placed on reducing off-gassing as much as possible.

One of the pieces of advice is to always choose HDF when shopping for laminate floors, if you can. The ressistance to moisture, and to shrinkage and expansion in HDF is much higher. This makes for a more stable core, which is the job of the core in any case – to give you a more stable floor overall. MDF will still serve you, of course. But, HDF is preferable for better performance.

Introduction

Medium density fiberwood (MDF) is a synthetic building material used in wooden constructions. Both softwood and hardwood are broken down into wood fibers in a defibrator which are then combined after treatment with resin and wax. These wood fibers are pressed at high temperatures and pressures to get MDF panels. With its introduction in the 1980s, MDF has been in existence for quite some time now. Its sturdiness and cost effectiveness have made it popular in constructions as well as manufacture of cabinets and cupboards. Along with its many advantages, MDF has its own disadvantages and here we shall discover the pros and cons of this relatively new building material over traditionally used wood.

Advantage of MDF Furniture

1.MDF is an economical choice. It's inexpensive to make so you will pay less for it in the store than for some solid wood pieces.

2.MDF uses recycled wood in its construction, thereby helping to save trees.

3.MDF is easy to paint in many different colours, whereas solid wood has a difficult time taking some colours.

A smooth material throughout, MDF does not have knots that can blemish the surface of a piece or make components difficult to attach.

4.The chemicals used in the construction of MDF make it poisonous to pests such as termites.

5.MDF will not expand and contract due to heat and humidity the way solid wood can.

6.Shaping MDF is easier than shaping solid wood, making it easier to do more elaborate designs.

Veneer can easily be attached to MDF to give it the look of genuine wood.

Disadvantages of MDF Furniture

1.As noted above, when MDF is being constructed, it may off-gas small amounts of formaldehyde, though this has largely dissipated by the end of the construction process. MDF which has been painted reduces any health risk still further.

2.MDF tends to be high maintenance - if you chip it or crack it, you cannot repair or cover the damage easily as you typically can with solid wood.

3.The chemicals used in making MDF make the material less child-friendly than other materials.

Direct exposure to water can cause MDF to swell.

4.There is no grain on MDF, as it is not a natural wood product. If this is an issue, however, it is easily remedied with veneer.

5.The glue present in MDF can make it hard to sink certain types of fasteners into the material.

Many people wondering the difference between MDF vs solid wood. MDF is an abbreviation for Medium Density Fiberboard. People tend to look down on MDF and automatically assume solid wood is the better choice.

Of course, solid wood, like anything has its pros and cons. The benefits of solid wood: it’s strong, sturdy, and features a beautiful natural look to it with grain patterns. If you’re looking for something to last forever, solid wood is a great choice. Each species of wood is different and some have longer longevity than others, but people are drawn to it. We love to have the authenticity of solid wood, which I completely understand. The beauty of natural wood is unbeatable.

However, wood contracts or expands when it is exposed to changing heat and humidity. Unless your home is a controlled climate, cabinets made from wood can shrink or crack over time. Something most people don’t even think about is the possibility of bug infestation in your wood. It is vulnerable to pests which means it requires some maintenance.

I’ve had so many people turn away the minute they hear there is MDF in a product. Man-made products are not as popular as the natural material. But why no love for this product? MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns. This will result in a smoother finish on the cabinets. MDF is also less expensive, which is sometimes a big selling point for some people. Depending on budget, others are willing to spend the extra money to purchase the all wood cabinets.

This new colour is custom-made, regular for furniture, cabinet, etc.

Colour is light beige,light grey, can be laminated on mdf, HMR mdf, etc.

Shipment is suit for bulk shipping ,container shipping/

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.