The UV High Gloss Board are made with UV coating applied to a panel surface that could be Melamine impregnated Pre-lam. UV means Ultra Violet Coating, ts core part is made of MDF wood and then it is given to UV coated coating. This is a process of drying the lacquer by UV rays in a series of closed chambers.

It will have 7 layer painting on the melamine paper.

The application in cupboard & kitchen shutters, furniture panels, wall relief panelling ,etc.

If you are interested in high gossy UV board , please see more at https://chinafiberboard.com/ This video shows how produce the UV board, this is bottom 5 floors, face 2 floors. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713 Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

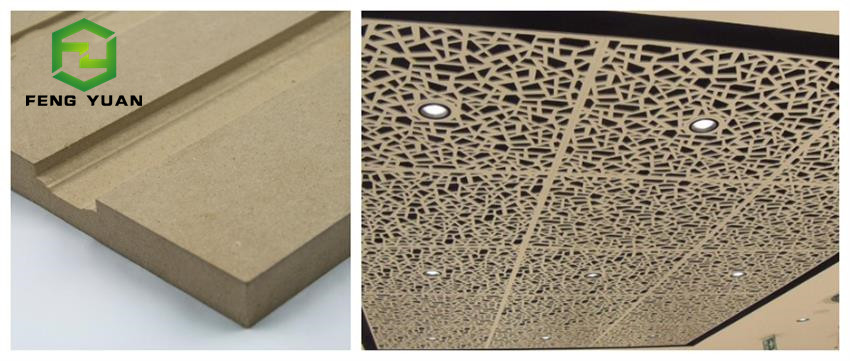

MDF is called medium density fiberboard, density ≥800 kg/m³ called HDF, means high density fiberboard.

So what are the advantages of MDF & HDF? Now let us explain it.

1. MDF & HDF is not easy to bend or crack. Although MDF is technically made of wood, its structure is completely different. If you try to bend the MDF board, it would rather grab rather than warp. This is why engineered wood has the advantage of different moisture resistance from its opponents. Of course, if you sink it into the water, the circuit board will be damaged sooner or later. However, if you expose it to moisture in the air, the part will expand and contract as a whole, while keeping the overall integrity and shape intact.

2. MDF & HDF is more affordable and easier to supply. Generally speaking, the price of MDF board is lower than that of natural wood. Of course, if you compare high-end MDF with some lower-priced wood, there are some exceptions. Another great benefit of engineered wood is that you will find it easier than maple or white oak, especially if you need a specific size.

3. MDF & HDF is easier to paint and seal. In contrast to solid wood, engineered wood does not have any specific texture or texture. This means that it is easier to sand and prime without having to worry about the appearance or the worst case-knots.

4. MDF & HDF is most suitable for cabinets. The advantages of engineered wood for cabinet doors are indisputable. The flexibility of manufacturing allows interior designers to choose between flat, partial, full coverage, embedded, European and raised designs. Many types of MDF have additional moisture resistance, which is essential for kitchen and bathroom furniture.

Plywood is a three-layer or multi-layer board-like material made of wood pieces that are peeled into veneer or sliced into veneer from wood, and then glued with adhesive. Usually, odd-numbered veneers are used, and adjacent veneers are used The fiber directions are glued perpendicular to each other.

Plywood is one of the commonly used materials for furniture and is one of the three major panels of wood-based panels. It can also be used as a material for aircraft, ships, trains, automobiles, buildings, and packaging boxes. A group of veneers is usually formed by gluing the adjacent layers of wood grains perpendicular to each other. The surface board and the inner board are usually arranged symmetrically on both sides of the central layer or the core. A slab made of glued veneers crisscrossed in the direction of the wood grain is pressed under heating or non-heating conditions. The number of layers is generally odd, and a few have even numbers. There is little difference in physical and mechanical properties in the vertical and horizontal directions. Commonly used types of plywood are three plywood, five plywood and so on. Plywood can improve the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, and the thickness specifications are generally: 3, 5, 9, 12, 15, 18mm , etc. The main tree species are: beech, camphor, willow, poplar, eucalyptus, etc.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.