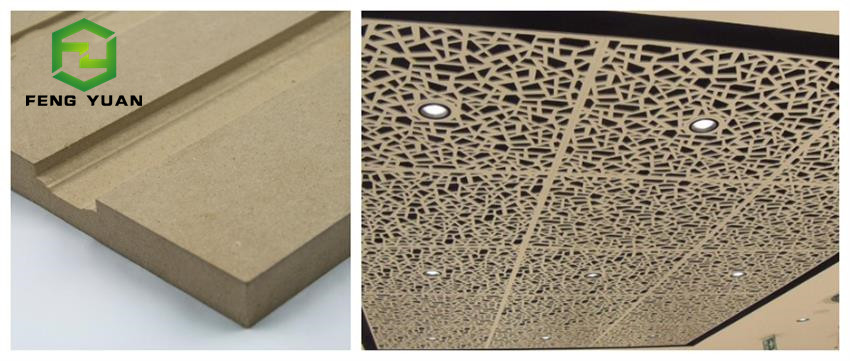

MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

MDF is called medium density fiberboard, density ≥800 kg/m³ called HDF, means high density fiberboard.

So what are the advantages of MDF & HDF? Now let us explain it.

1. MDF & HDF is not easy to bend or crack. Although MDF is technically made of wood, its structure is completely different. If you try to bend the MDF board, it would rather grab rather than warp. This is why engineered wood has the advantage of different moisture resistance from its opponents. Of course, if you sink it into the water, the circuit board will be damaged sooner or later. However, if you expose it to moisture in the air, the part will expand and contract as a whole, while keeping the overall integrity and shape intact.

2. MDF & HDF is more affordable and easier to supply. Generally speaking, the price of MDF board is lower than that of natural wood. Of course, if you compare high-end MDF with some lower-priced wood, there are some exceptions. Another great benefit of engineered wood is that you will find it easier than maple or white oak, especially if you need a specific size.

3. MDF & HDF is easier to paint and seal. In contrast to solid wood, engineered wood does not have any specific texture or texture. This means that it is easier to sand and prime without having to worry about the appearance or the worst case-knots.

4. MDF & HDF is most suitable for cabinets. The advantages of engineered wood for cabinet doors are indisputable. The flexibility of manufacturing allows interior designers to choose between flat, partial, full coverage, embedded, European and raised designs. Many types of MDF have additional moisture resistance, which is essential for kitchen and bathroom furniture.

What is Hot pressing for hardboard? This is the questions we asked mostly from our clients, let's discuss it together.

The hot-pressed wet-process method produces a hard-fiber board with a pressure of 5 MPa and a dry method of 7 MPa. Above this pressure, the bending strength is reduced. The pressure required for the semi-dry method is between the two, at 6 MPa. The wet-formed slab is pressed into a hard fiberboard at a pressure of up to 10 MPa. The temperature used in the wet pressing method is 200 to 220 °C.

There is no drying stage when dry pressing, the temperature is based on the rapid curing of the adhesive, generally 180 ~ 200 ° C; when using hardwood as raw material, the hot pressing temperature can be appropriately increased, up to 260 ° C. The semi-dry hot pressing temperature should not exceed 200 ° C to prevent the melting of lignin and sugar hydrolysis coking in the slab, so that the strength of the product is significantly reduced.

The temperature required to produce a hard board by wet drying is 230 to 250 °C. During the hot pressing process, the temperature difference between the surface layer and the core layer of the slab may occur, and the temperature difference of the core layer of the medium-density slab having a large thickness may reach 40 to 60 ° C, which affects the curing rate of the core resin. Conventional heating and high frequency heating can be used to eliminate temperature differences and shorten the hot pressing cycle.

After hot processing, hardboard, mdf, plywood will be have a good quality & stable technical nature.

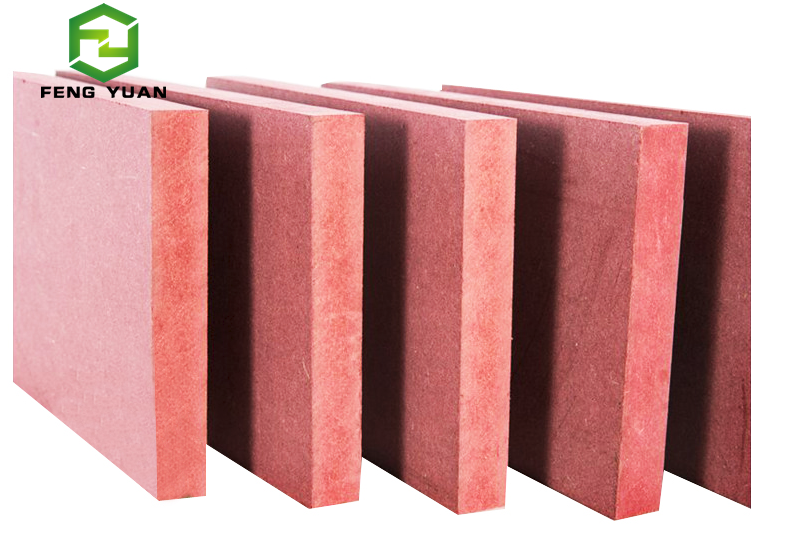

When buying boards, I wonder if you have noticed such a special board -fire-retardant MDF board. The intuitive characteristic of this type of board is the red or pink appearance, which is distinguished from ordinary density boards by adding red dye during the production process. Its flame-retardant properties are also formed by adding flame-retardant chemical components during the manufacturing process.

Fire-retardant panels have attracted a lot of attention since they came out. Because of their superior flame-retardant and safety performance than ordinary MDF, it has been widely used in international brand display props, entertainment venues decoration, domestic shopping malls Cinemas, airports, hotels and other public places.

Due to the uneven quality of the fire-retardant boards circulating in the market, how to buy high-quality fire-retardant MDF? Here, FengYuan will briefly introduce to you the three purchase techniques of fire-retardant MDF:

1. Brand identification method

Flame-retardant MDF is a product with relatively high production technology requirements. Generally speaking, only larger manufacturers have the ability to produce. When buying flame-retardant MDF, pay attention to the side of the board. Big brands will indicate their factory name, flame-retardant grade and other information on the edge.

2. Flame retardant report identification method

When purchasing, you can ask the dealer to provide the flame retardant grade test report, the test report will list the flame retardant grade of the board in detail, and the parameter information is for the purchaser to view. Since most manufacturers will only test some representative sizes, when the required size is not reported, it is also possible to select a test report of a similar size.

3. Identification method of excellent dealers

It is also a better way to choose an excellent and well-known board distributor. Such distributors have a long history of development, possess brand value, and have more reliable board quality.

As one of the company's high-quality products, the flame-retardant board has indeed been favored by many buyers for its own excellent performance, and its future application scope and development space will be broader.

Many people wondering the difference between MDF vs solid wood. MDF is an abbreviation for Medium Density Fiberboard. People tend to look down on MDF and automatically assume solid wood is the better choice.

Of course, solid wood, like anything has its pros and cons. The benefits of solid wood: it’s strong, sturdy, and features a beautiful natural look to it with grain patterns. If you’re looking for something to last forever, solid wood is a great choice. Each species of wood is different and some have longer longevity than others, but people are drawn to it. We love to have the authenticity of solid wood, which I completely understand. The beauty of natural wood is unbeatable.

However, wood contracts or expands when it is exposed to changing heat and humidity. Unless your home is a controlled climate, cabinets made from wood can shrink or crack over time. Something most people don’t even think about is the possibility of bug infestation in your wood. It is vulnerable to pests which means it requires some maintenance.

I’ve had so many people turn away the minute they hear there is MDF in a product. Man-made products are not as popular as the natural material. But why no love for this product? MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns. This will result in a smoother finish on the cabinets. MDF is also less expensive, which is sometimes a big selling point for some people. Depending on budget, others are willing to spend the extra money to purchase the all wood cabinets.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.