MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

One of the key areas to ask about when shopping for laminate and engineered wood floors is the core layer, which we talk about a bit on our 5 Things You Need To Know Before You Buy Laminate Flooring. The materials typically used in the making of a core layer is high-density fiberboard (HDF) and medium-density fiberboard (MDF). Given that it is an important aspect when it comes to the anatomy of a floor, and important when you’re buying floors, I thought it made sense to talk about it a bit.

Fiberboard is a wood byproduct, known as an engineered wood product because raw materials are taken and processed into a versatile and durable material. It’s used in flooring as core material, of course. But, it’s also used for furniture manufacturing, designed not to split or crack.

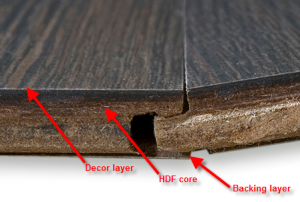

Fiberboard is made through a compression process, where wood fibers are bonded together, specifically for the use of backing or of reinforcing a veneer, and most often with a resin to keep it stable. On laminate flooring and engineered hardwood floors, the fiberboard core are sandwiched between the decor layer or veneer layer, and the backing layer.

Take a look:

HDF is MDF are made in a similar process, although the compression levels are in a slightly lower range with MDF from 600-800 kg/m3. HDF is processed in a range from 600-1450 kg/M3. Fiberboard cores are checked for emissions levels, both when they’re manufactured, and afterward too before they’re shipped as product. This is mainly due to the use of resins and glue that are used to bind the materials, and the importance placed on reducing off-gassing as much as possible.

One of the pieces of advice is to always choose HDF when shopping for laminate floors, if you can. The ressistance to moisture, and to shrinkage and expansion in HDF is much higher. This makes for a more stable core, which is the job of the core in any case – to give you a more stable floor overall. MDF will still serve you, of course. But, HDF is preferable for better performance.

Wood venner is a wood flake material produced by rotary cutting or sawing. Its thickness is usually between 0.4-2.0mm, which is mainly used to produce plywood and other plywood. Generally, high-quality veneer is used as the panel of plywood, blockboard, formwork, veneer, and other artificial boards. Graded veneers can be used as backboards and core boards.

Veneer is a product that consumes a lot of labor. There are many such kind of products.

How to select a good veneer?

Size and hardness considerations:

A ) Length: Generally speaking, the longer the veneer, the more stable it is, suitable for high-speed taxiing, and the shorter the board, the more flexible it is, suitable for use in parks and props. But which range is more appropriate? Presumably everyone already has a certain understanding. Stand up the board, no higher than your nose, and no lower than your shoulders. Someone here might ask, isn't it between the chin and the nose? BOARDZONE here refers to the length exclusive to playing props (almost all foreign PROs have two lengths, respectively, for high-speed taxis such as large jump platforms or mountains that require speed, and short boards used in parks and props) ). And the shortest length for prop movement is suitable around the shoulder.

B) Width: Generally speaking, the board selected according to height is basically suitable in width, but some players with larger feet may find that the board is long enough and not wide enough (the standard is to place the retainer and boots at a customary angle. After that, if there are too many parts that are wider than the board surface—for example, all 5 feet are outside—the board is not wide enough, and it is easy to accidents because the board cannot slide normally when sliding. Note, however, that boots and holders that are slightly wider than the board are normal.

C)Hardness: Hardness is also a key choice when choosing a veneer. Generally speaking, the harder the board is, the more stable it is at high speeds, suitable for maintaining speed. The softer the board is, the easier it is to complete the fancy action in FREESTYLE. You should choose different hardness according to your favorite way of sliding. One thing that BOARDZONE wants to remind everyone here is also often overlooked: the body weight also plays a big role in choosing different types of hardness. For people of the same height, the heavier one should use the harder board, while the lighter one can choose the softer board. General veneer companies have different standards on the different products introduced, indicating their suitable taxiing methods and player weights, etc., everyone should pay attention to reference when choosing. Because different companies have different standards for different models, BOARDZONE will not list them here.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.