This questions has been asked by many persons, now let's introduce MDF here.

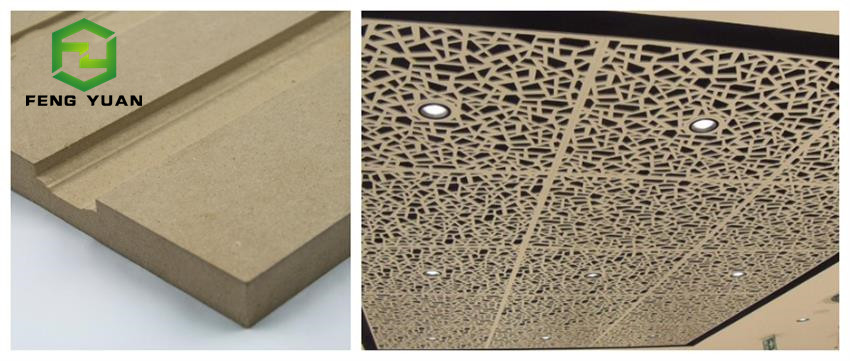

MDF , the full name is Medium Density Fiberboard, that’s an inexpensive and durable option for many carpentry projects. Medium-density fiberboard is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting.

MDF is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure, it also can be called fiberboard, some high density ≥800,called HDF, but it only have density & thickness difference.

MDF is a versatile building material. It’s cost-effective and good for use on shelving, storage cabinets, and decorative projects. It also has a smooth surface, which is perfect for painting

Yes, the contect of formadehydele can be controlled, the grade can be E1, E0, some grade will be lower than logs.

Advantages of MDF Wood

MDF is inexpensive.

MDF uses recycled wood, which is environmentally-friendly.

Veneers can be attached to MDF to make it look like real wood.

MDF will not expand and contract in the heat and humidity like solid wood can.

MDF is easy to paint in a variety of colors and easier to shape than solid wood.

MDF doesn’t have knots that can make a piece hard to attach.

MDF is resistant to pests, such as termites, due to the chemicals used in its construction.

Disadvantages of MDF Wood

If MDF is chipped or cracked, you cannot repair or cover it easily.

MDF can swell if it touches water.

There’s no natural grain on MDF wood.

Small amounts of formaldehyde may be off-gassed during construction, and it’s less child-friendly than solid wood.

MDF has glue in it that can make it hard to sink certain types of fasteners into it.

If you are interested in MDF,HDF, MELAMINE MDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. You could find out that our boards are in very good features, and these boards can be used in various places, like furniture and decorations and some you may not imagine before, like computers and cars. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

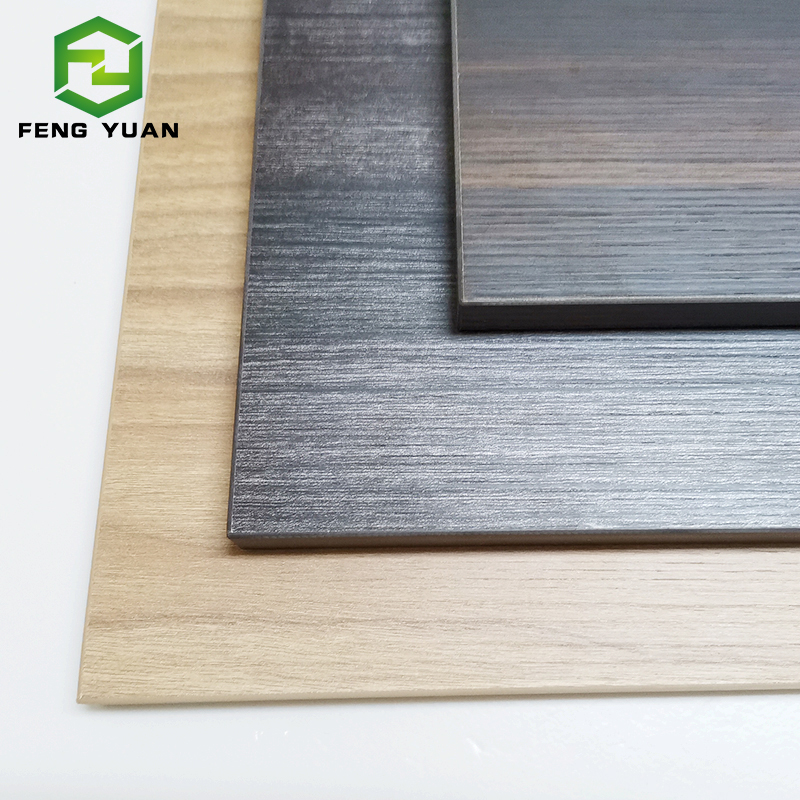

MDF stands for Medium Density Fibreboard and is made from wood fibres glued together under high heat and pressure. Melamine MDF is melamine paper coated on MDF, have various of colours, E0/E1/E2 glue,it is widely used for furniture, desk, doors , and other decration etc.

The melamine covered MDF core consists of wood fibres. That gives it a flat and smooth surface, dimensional stability, high density, and features that make it easy for processing. You can get it in different thickness, decorative finishes and designs to one or both sides.

It usually widely used for different applications.

Melamine-faced MDF sheets are utilised in a myriad of applications including making:

It is also worth noting that because of its dimensionally stable and smooth surface, melamine covered MDF is also utilised for laminate veneers or decorative wood.

If you are interested in our Thin MDF and HDF board, please see more at https://chinafiberboard.com/ This video shows how the continuous machine line produce thin mdf or hdf board. We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely. We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whatsapp: +8615868403313

Email: sales@fengyuanwooden.com

All the wood based panel which using melamine Laminate technology can be called melamine boards. Common melamine board based with MDF board, particleboard, and plywood. Melamine MDF board, as the name implies, is based of MDF, melamine paper can be various colours, white, black, wood grain,etc.

Usually, when we talk about Melamine boards, we talk about Laminates and baseboards. But in fact is much more complexed. Laminate is generally composed of ① surface paper, ②decorative paper, ③cover paper, and ④bottom paper.

① The surface paper is placed on the top layer of the decorative board. It protects the decorative paper and makes the surface of the board after heating and pressing highly transparent. The board surface is hard and abrasion-resistant. This paper requires good water absorption, white and clean, and transparent after dipping.

② Decorative paper, that is, wood grain paper, is an important part of the decorative board. It has a base color or no base color and is printed into various patterns of decorative paper. It is placed under the surface paper and mainly plays a decorative role. This layer requires Paper has good hiding power, impregnation, and printing performance.

③ Cover paper, also called titanium white paper, is generally placed under decorative paper when manufacturing light-colored decorative boards to prevent the underlying phenolic resin from penetrating the surface. Its main function is to cover the color spots on the surface of the substrate. Therefore, good coverage is required. The above three types of paper were each impregnated with melamine resin.

④ Bottom paper is the base material of the decorative board. It plays a role in the mechanical properties of the board. It is made by impregnating with phenolic resin glue and dried. Several layers can be determined according to the application or the thickness of the decorative board during production.

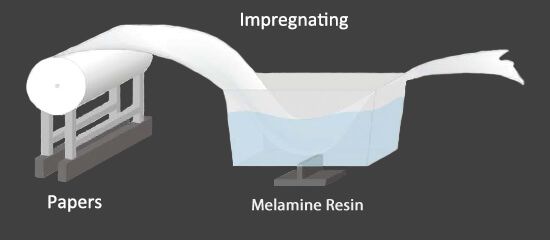

To turn the papers to laminates, we need to impregnating them in melamine resins, mealmine resin is used for stick the paper on surface of MDF.

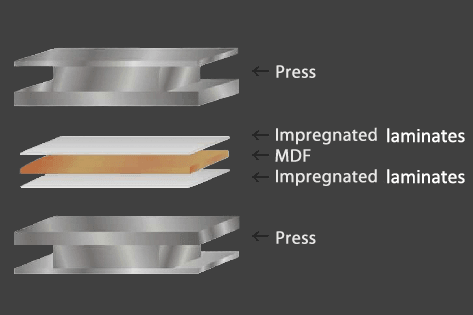

when we had Melamine Laminates, then use a hot press machine to laminated it with MDF Board.

This the process how the melamine MDF board be produced.The Impregnating Process normally finished by the laminates factory, then we buy melamine laminates from them and produce melamine Paper

You can also view the above video to see how it works.

If you are interested in melamine melamine MDF , please see more at https://chinafiberboard.com/

We warmly welcome wholesalers, traders, furniture factories, construction projects team to contact us freely.

We definitely will provide you with both high quality goods and great service.

Hangzhou Fengyuan Wood Co.,Ltd

Web: https://chinafiberboard.com/

Tel: +86-571-86063713

Whats app: +8615868403313

Email: sales@fengyuanwooden.com

Introduction

Medium density fiberwood (MDF) is a synthetic building material used in wooden constructions. Both softwood and hardwood are broken down into wood fibers in a defibrator which are then combined after treatment with resin and wax. These wood fibers are pressed at high temperatures and pressures to get MDF panels. With its introduction in the 1980s, MDF has been in existence for quite some time now. Its sturdiness and cost effectiveness have made it popular in constructions as well as manufacture of cabinets and cupboards. Along with its many advantages, MDF has its own disadvantages and here we shall discover the pros and cons of this relatively new building material over traditionally used wood.

Advantage of MDF Furniture

1.MDF is an economical choice. It's inexpensive to make so you will pay less for it in the store than for some solid wood pieces.

2.MDF uses recycled wood in its construction, thereby helping to save trees.

3.MDF is easy to paint in many different colours, whereas solid wood has a difficult time taking some colours.

A smooth material throughout, MDF does not have knots that can blemish the surface of a piece or make components difficult to attach.

4.The chemicals used in the construction of MDF make it poisonous to pests such as termites.

5.MDF will not expand and contract due to heat and humidity the way solid wood can.

6.Shaping MDF is easier than shaping solid wood, making it easier to do more elaborate designs.

Veneer can easily be attached to MDF to give it the look of genuine wood.

Disadvantages of MDF Furniture

1.As noted above, when MDF is being constructed, it may off-gas small amounts of formaldehyde, though this has largely dissipated by the end of the construction process. MDF which has been painted reduces any health risk still further.

2.MDF tends to be high maintenance - if you chip it or crack it, you cannot repair or cover the damage easily as you typically can with solid wood.

3.The chemicals used in making MDF make the material less child-friendly than other materials.

Direct exposure to water can cause MDF to swell.

4.There is no grain on MDF, as it is not a natural wood product. If this is an issue, however, it is easily remedied with veneer.

5.The glue present in MDF can make it hard to sink certain types of fasteners into the material.

Wood venner is a wood flake material produced by rotary cutting or sawing. Its thickness is usually between 0.4-2.0mm, which is mainly used to produce plywood and other plywood. Generally, high-quality veneer is used as the panel of plywood, blockboard, formwork, veneer, and other artificial boards. Graded veneers can be used as backboards and core boards.

Veneer is a product that consumes a lot of labor. There are many such kind of products.

How to select a good veneer?

Size and hardness considerations:

A ) Length: Generally speaking, the longer the veneer, the more stable it is, suitable for high-speed taxiing, and the shorter the board, the more flexible it is, suitable for use in parks and props. But which range is more appropriate? Presumably everyone already has a certain understanding. Stand up the board, no higher than your nose, and no lower than your shoulders. Someone here might ask, isn't it between the chin and the nose? BOARDZONE here refers to the length exclusive to playing props (almost all foreign PROs have two lengths, respectively, for high-speed taxis such as large jump platforms or mountains that require speed, and short boards used in parks and props) ). And the shortest length for prop movement is suitable around the shoulder.

B) Width: Generally speaking, the board selected according to height is basically suitable in width, but some players with larger feet may find that the board is long enough and not wide enough (the standard is to place the retainer and boots at a customary angle. After that, if there are too many parts that are wider than the board surface—for example, all 5 feet are outside—the board is not wide enough, and it is easy to accidents because the board cannot slide normally when sliding. Note, however, that boots and holders that are slightly wider than the board are normal.

C)Hardness: Hardness is also a key choice when choosing a veneer. Generally speaking, the harder the board is, the more stable it is at high speeds, suitable for maintaining speed. The softer the board is, the easier it is to complete the fancy action in FREESTYLE. You should choose different hardness according to your favorite way of sliding. One thing that BOARDZONE wants to remind everyone here is also often overlooked: the body weight also plays a big role in choosing different types of hardness. For people of the same height, the heavier one should use the harder board, while the lighter one can choose the softer board. General veneer companies have different standards on the different products introduced, indicating their suitable taxiing methods and player weights, etc., everyone should pay attention to reference when choosing. Because different companies have different standards for different models, BOARDZONE will not list them here.

Physical and mechanical properties

Because of its uniform structure and high bonding strength between fibers, it has good static bending strength, plane tensile strength and elastic modulus. However, because MDF is made of wood, it completely changes the structure of wood, so its water absorption, water absorption, thickness expansion rate is higher, nail grip strength is worse than particleboard.

Decorative performance

Because the surface of MDF is smooth, it is easy to stick veneer materials such as veneer and tissue paper, so it is easy to paint and save paint.

Additive performance

MDF can be produced from several millimeters to tens of millimeters in thickness. It can replace wood and square wood of any thickness, and has good machinability, sawing, drilling, grooving, tenoning, sanding and carving.

MDF is called medium density fiberboard, density ≥800 kg/m³ called HDF, means high density fiberboard.

So what are the advantages of MDF & HDF? Now let us explain it.

1. MDF & HDF is not easy to bend or crack. Although MDF is technically made of wood, its structure is completely different. If you try to bend the MDF board, it would rather grab rather than warp. This is why engineered wood has the advantage of different moisture resistance from its opponents. Of course, if you sink it into the water, the circuit board will be damaged sooner or later. However, if you expose it to moisture in the air, the part will expand and contract as a whole, while keeping the overall integrity and shape intact.

2. MDF & HDF is more affordable and easier to supply. Generally speaking, the price of MDF board is lower than that of natural wood. Of course, if you compare high-end MDF with some lower-priced wood, there are some exceptions. Another great benefit of engineered wood is that you will find it easier than maple or white oak, especially if you need a specific size.

3. MDF & HDF is easier to paint and seal. In contrast to solid wood, engineered wood does not have any specific texture or texture. This means that it is easier to sand and prime without having to worry about the appearance or the worst case-knots.

4. MDF & HDF is most suitable for cabinets. The advantages of engineered wood for cabinet doors are indisputable. The flexibility of manufacturing allows interior designers to choose between flat, partial, full coverage, embedded, European and raised designs. Many types of MDF have additional moisture resistance, which is essential for kitchen and bathroom furniture.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.