One of the key areas to ask about when shopping for laminate and engineered wood floors is the core layer, which we talk about a bit on our 5 Things You Need To Know Before You Buy Laminate Flooring. The materials typically used in the making of a core layer is high-density fiberboard (HDF) and medium-density fiberboard (MDF). Given that it is an important aspect when it comes to the anatomy of a floor, and important when you’re buying floors, I thought it made sense to talk about it a bit.

Fiberboard is a wood byproduct, known as an engineered wood product because raw materials are taken and processed into a versatile and durable material. It’s used in flooring as core material, of course. But, it’s also used for furniture manufacturing, designed not to split or crack.

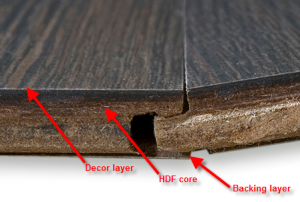

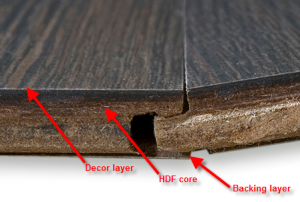

Fiberboard is made through a compression process, where wood fibers are bonded together, specifically for the use of backing or of reinforcing a veneer, and most often with a resin to keep it stable. On laminate flooring and engineered hardwood floors, the fiberboard core are sandwiched between the decor layer or veneer layer, and the backing layer.

Take a look:

HDF is MDF are made in a similar process, although the compression levels are in a slightly lower range with MDF from 600-800 kg/m3. HDF is processed in a range from 600-1450 kg/M3. Fiberboard cores are checked for emissions levels, both when they’re manufactured, and afterward too before they’re shipped as product. This is mainly due to the use of resins and glue that are used to bind the materials, and the importance placed on reducing off-gassing as much as possible.

One of the pieces of advice is to always choose HDF when shopping for laminate floors, if you can. The ressistance to moisture, and to shrinkage and expansion in HDF is much higher. This makes for a more stable core, which is the job of the core in any case – to give you a more stable floor overall. MDF will still serve you, of course. But, HDF is preferable for better performance.

Copyright © 2024. Hangzhou Fengyuan Wood Co.,Ltd All rights reserved.